Sustainability

Sustainability matters to us, and when you consider the facts, it's clear why it matters to your business, too. Traditional apparel production uses virgin natural and chemical resources, which puts massive pressure on our environment. Baichaun has dedicated our business to providing sustainable options for you that are high in quality and lower the impact on our natural world.

Across our factories, we have implemented measures to ensure we operate as sustainably as possible.

Solar Panels

Our yarn factory has a solar panel system that can generate 2,800,000 kWh per year, and its photovoltaic capacity is 2.69MW.

Our newly built fabric factory's solar panel system can generate 2,500,000 kWh per year, and the photovoltaic capacity is 2.00 MW.

Water Treatment

The water treatment system in our new fabric factory can process 9000 tonnes of wastewater from our production line and reuse 90% of it for weaving production.

How we do it

Completely vertical, we do it all on-site

Collect

Post-consumer PET water bottles are gathered through our waste collection partners.

Shred

Bottles are shredded into recycled PET flakes and thoroughly cleaned.

Dope-Dye

PET flakes are turned into a solution, and pigments are added directly to it. This substance is then extruded to become colored yarn.

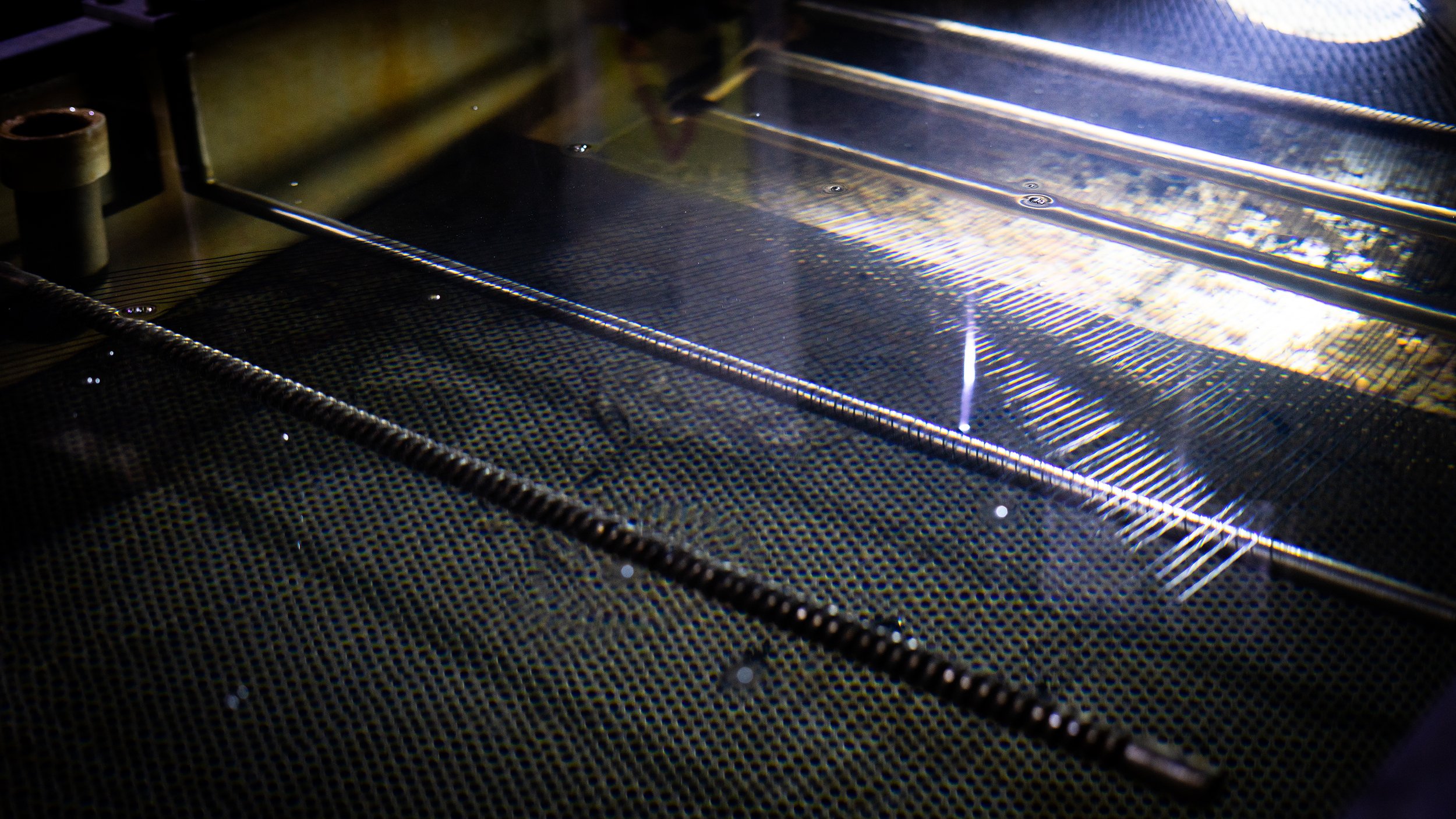

Weave

Yarns are then woven into various colored fabrics.

Why Dope-dye?

Compared with traditional piece-dyed recycled polyester, every 100 tonne of dope-dyed fabric saves

14,000 tonnes of water

The water consumption of 1,000 households for a whole year

400 tonnes of CO2

The amount absorbed by 2,300 trees in a year

5,000 GJ

The electricity consumption of 10,600 households in a year

More color, less pollution

Dope-dyeing is environmentally superior to traditional dyeing. It reduces water usage, minimises the need for harmful chemicals, and lowers energy consumption during dyeing, significantly reducing your product's eco-footprint.

Baichuan has developed a catalogue of over 1000 dope-dyed colours, giving you more design freedom. We work closely with dyeing experts to achieve brilliant colour options for your products.

The apparel industry uses excessive water and toxic chemicals to make raw materials and clothing. This makes textile dyeing the second largest polluter of clean water globally after agriculture and further strengthens the case for cleaner, more sustainable practices, like dope-dyeing in the textile industry.

Every ton of dope dyed yarn produced saves 15 tons of water, 2 tons of steam and 1 ton of coal. It also reduces the discharge of 15 tons of printing and dyeing wastewater, as well as 24kg of sulfur dioxide, 25kg of smoke and 144kg of slag.

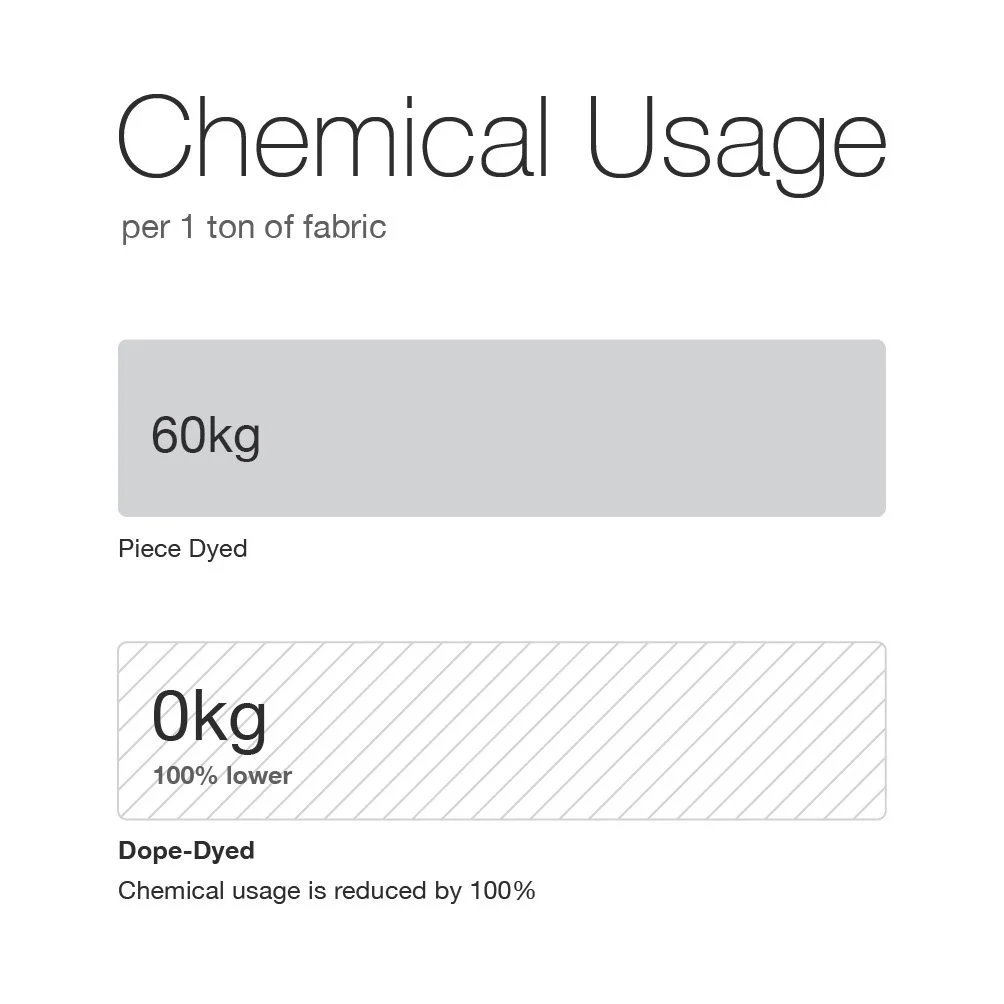

Dope dyeing offers significant environmental benefits by eliminating the need for chemical additives during the dyeing process.

Traditional methods typically require around 60kg of chemicals per ton of fabric, but with dope dyeing, this figure is reduced to zero—resulting in a 100% reduction in chemical use. Additionally, dope dyeing greatly minimizes pigment consumption. While conventional piece dyeing requires 5kg of pigments per ton of fabric, dope dyeing only uses 1.5kg, reducing pigment usage by an impressive 70%.

In conventional piece dyeing, processing 1 ton of fabric requires 8kg of sodium hydroxide, 80kg of PAC (Polyaluminum Chloride), and 0.8kg of PAM (Polyacrylamide) to treat the wastewater. With dope dyeing, these chemicals are no longer necessary, reducing the need for sodium hydroxide, PAC, and PAM entirely.

1 tonne of dope-dyed polyester yarn will save

15 tons of water — 2 tons of steam — 1 ton of coal

And also reduces the discharge of

15 tons of printing and dyeing wastewater — 24kg of sulfur dioxide — 25kg of smoke — 144kg of slag

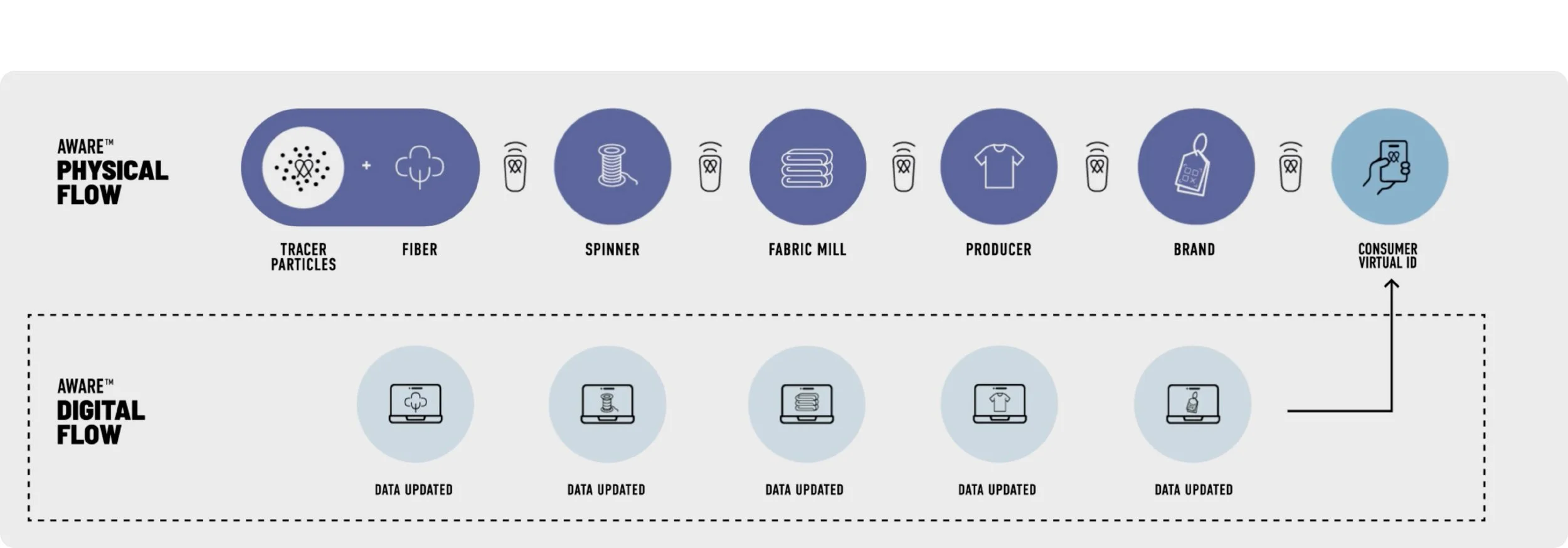

Our partnership

Baichuan has partnered with Aware™, the leading traceability solution. Using batch-level digital twins stored on blockchain, Aware™ enables verification of the recycled material’s journey from waste to finished fabric.